Unleashing Innovation with 3D Rapid Prototyping in Metal Fabrication

The evolution of technology has opened up new avenues for businesses, particularly in the manufacturing sector. One such groundbreaking technology that is reshaping the landscape of metal fabrication is 3D rapid prototyping. This innovative approach not only saves time and resources but also enhances design precision and flexibility. In this comprehensive article, we will delve into the world of 3D rapid prototyping, its benefits, applications, and how it is transforming the metal fabrication industry.

Understanding 3D Rapid Prototyping

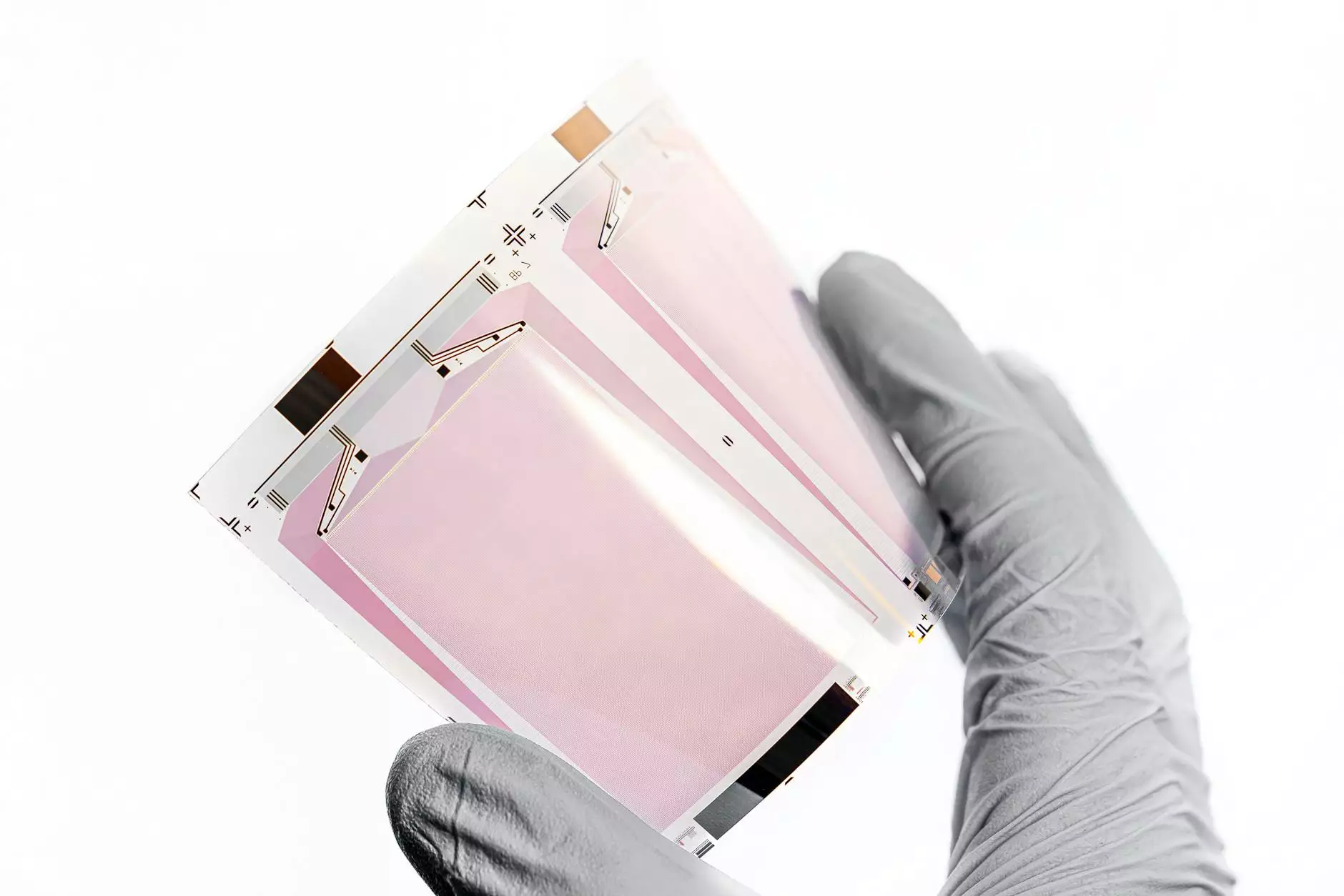

3D rapid prototyping refers to a series of processes used to create three-dimensional objects from a digital file. This technology involves various additive manufacturing techniques, where thin layers of materials are successively laid down to form the final product. This is a departure from traditional subtractive manufacturing methods, where material is removed from a solid block to create components.

In the context of metal fabrication, 3D rapid prototyping employs metals such as steel, aluminum, titanium, and other alloys to produce precise and complex parts. It allows for rapid iteration of designs, enabling engineers and designers to test and refine their concepts quickly.

The Process of 3D Rapid Prototyping

The process of 3D rapid prototyping can be broken down into several key stages:

- Design Creation: The process begins with a digital model, commonly created using computer-aided design (CAD) software. This model serves as the blueprint for the prototyping process.

- Preparation for Printing: The digital model is converted into a format compatible with 3D printers, usually STL (Standard Tessellation Language). This step includes slicing the model into layers, which informs the printer how to build up the object layer by layer.

- 3D Printing: The actual printing process occurs here. Depending on the technology used—such as selective laser melting (SLM), electron beam melting (EBM), or binder jetting—metal powders are fused together to create the part.

- Post-Processing: After printing, the prototype often requires post-processing steps, such as cleaning, surface finishing, and heat treatment, to achieve the desired mechanical properties and aesthetic appeal.

Benefits of 3D Rapid Prototyping in Metal Fabrication

The adoption of 3D rapid prototyping within the metal fabrication sector brings numerous advantages, including:

- Enhanced Design Flexibility: Designers can easily modify and iterate on designs without the constraints of traditional manufacturing methods.

- Reduced Lead Times: Rapid prototyping significantly cuts down the time from concept to production, allowing companies to bring products to market faster.

- Cost Efficiency: By minimizing the material waste and reducing the need for complex tooling, companies can lower production costs.

- Complex Geometries: 3D rapid prototyping allows the creation of intricate shapes and structures that may be impossible with conventional methods.

- Improved Performance: Prototyping and testing designs can lead to better-performing end products as flaws can be identified and corrected early in the design process.

Applications of 3D Rapid Prototyping in Metal Fabrication

The applications of 3D rapid prototyping are vast and varied across multiple industries:

Aerospace Industry

In the aerospace sector, weight reduction is critical. 3D rapid prototyping enables manufacturers to create lightweight components with complex geometries, ultimately enhancing fuel efficiency and performance.

Automotive Industry

Automakers utilize 3D rapid prototyping for rapid design testing and evaluation of parts. This technology accelerates the development of new models while ensuring quality and performance standards are met.

Medical Devices

The healthcare sector benefits from customized medical devices tailored to individual patient needs. 3D rapid prototyping facilitates the production of patient-specific implants and surgical tools.

Consumer Products

From electronics to fashion items, the consumer product industry leverages 3D rapid prototyping to create innovative products that meet the fast-paced demands of today's market.

The Future of 3D Rapid Prototyping in Metal Fabrication

As technology continues to advance, the future of 3D rapid prototyping in metal fabrication looks promising. Innovations in materials and printing techniques are expected to enhance the capabilities of 3D printers and expand the horizons of what can be manufactured. Moreover, the integration of artificial intelligence and machine learning may further optimize design processes and production efficiency.

Further, with the trend towards sustainability growing in importance, 3D rapid prototyping presents a pathway for companies to reduce waste and improve energy efficiency during production. As businesses increasingly adopt environmentally friendly practices, the role of rapid prototyping will likely expand, allowing for the production of sustainable products without compromising quality.

Conclusion

In conclusion, 3D rapid prototyping represents a significant advancement in the field of metal fabrication. By streamlining the design and manufacturing process, this technology empowers businesses to innovate rapidly and efficiently. For companies in the metal fabrication segment, embracing 3D rapid prototyping can lead to a competitive edge in today's fast-paced market. As we look to the future, the integration of this transformative technology will undoubtedly play a pivotal role in shaping the landscape of manufacturing and product development.

With the growing demand for products that are not only high-quality but also delivered quickly and at lower costs, utilizing 3D rapid prototyping is no longer just an option; it is a necessity for staying relevant and competitive in the industry. If you're ready to elevate your metal fabrication processes, consider investing in their 3D rapid prototyping solutions today.

3 d rapid prototyping